The magnetic particle testing (also magnetic particle crack detection) is a technique to detect cracks in or close to the surface of ferromagnetic materials.

The material has to be magnetised for the test. For bigger testing objects, where a full magnetisation is not possible, the objects are only partially magnetised. The field lines, which occur as a result of the magnetisation, run parallel to the surface. Cracks and surface-near defects which lie crossways to the field lines produce a magnetic leakage field. This means the field lines leave the surface defect on one side of the ferromagnetic material and enter on the other side. This leads to the formation of magnetic poles. Subsequently iron powder is attached to the magnetic leakage field, which gathers itself in the faulty area. Cracks that run parallel to the field lines do not produce a magnetic leakage field and can therefore not be detected. Pores and cracks can only be verified up to a certain depth.

With this method the object is flooded with electric current. This current produces a circular magnetic field. Cracks which run parallel to the object can therefore be detected due to their alignment perpendicular to the field lines and produce the necessary magnetic leakage field.

In other words:

The current flooding method detects longitudinal cracks.

In contrast to the current flow detection the field flow detection produces a magnetic field in the tested object without a flow of electric current.

The magnetic field is produced in a U-shaped iron yoke of one or several energized coils. The tested component is mounted into the iron yoke. Thus a magnetic field longitudinal to the tested component is produced. Transverse cracks build a magnetic flux leakage and are therefore indicated.

In many tested objects cracks cannot be expected in a specific direction. In this case either several different techniques have to be performed consecutively or combined techniques can be used.

The simplest combination is a direct current yoke magnetisation and an alternating current flow. The testing appliance is conceived to the effect that the current is induced in the tested sample via the magnetic poles simultaneously. The magnetic yoke has to be insulated once in order to prevent a shunt.

At the magnetic particle crack testing the iron particles are attached during the magnetisation. Finely powdered particles, mostly ferromagnetic iron oxides, indicate even tiny hair cracks. The powder particles are floated with fluids such as water and are poured or sprayed over the tested device during the magnetisation.

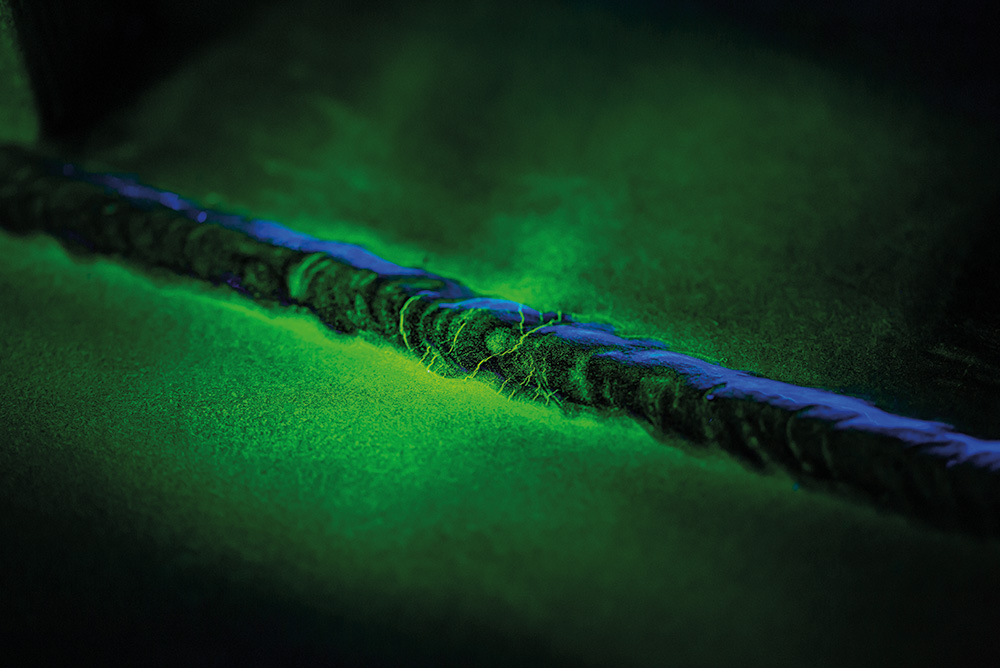

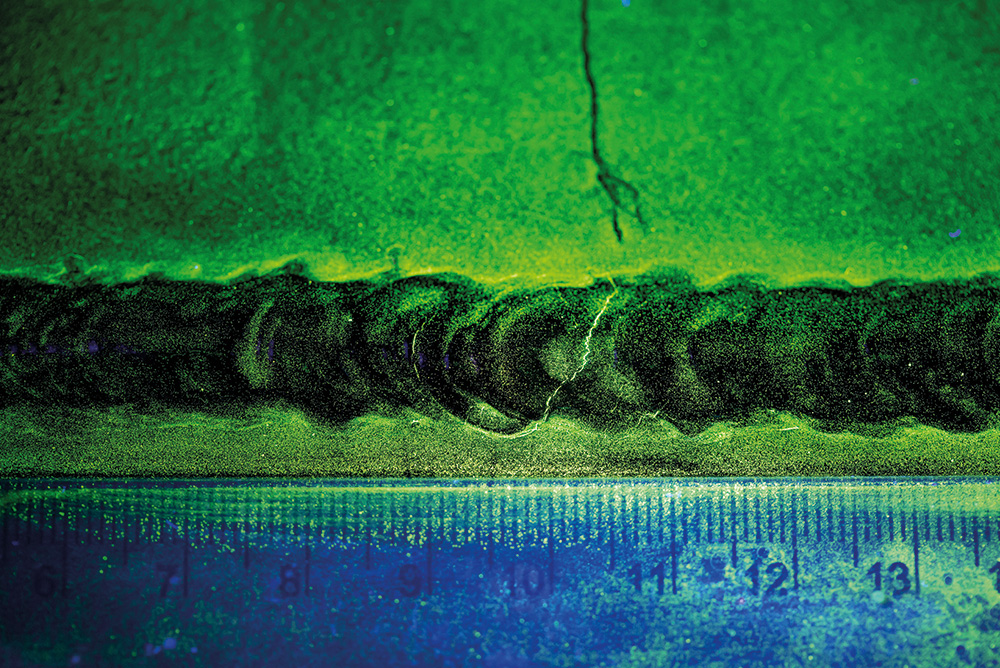

At the magnetic crack detection with fluorescent testing methods the indicating magnetic particles are connected tightly and permanently with the colour pigments, which illuminate brightly in yellow, green or red when exposed to light with a wavelength range of 300-500 nm. The occurring contrast enhancement provides an easier detection of the crack.

Get an insight into our work.

DIN 25435-2, Wiederkehrende Prüfungen der Komponenten des Primärkreises von Leichtwasserreaktoren – Teil 2: Magnetpulver- und Eindringprüfung

ÖN EN 1330-7, Zerstörungsfreie Prüfung – Terminologie – Teil 7: Begriffe der Magnetpulverprüfung

ÖN EN 1369, Gießereiwesen – Magnetpulverprüfung

ÖN EN 10228-1, Zerstörungsfreie Prüfung von Schmiedestücken aus Stahl – Teil 1: Magnetpulverprüfung

ÖN EN 10246-12, Zerstörungsfreie Prüfung von Stahlrohren – Teil 12: Magnetpulverprüfung nahtloser und geschweißter ferromagnetischer Stahlrohre zum Nachweis von Oberflächenfehlern

ÖN EN 10246-18, Zerstörungsfreie Prüfung von Stahlrohren – Teil 18: Magnetpulverprüfung der Rohrenden nahtloser und geschweißter ferromagnetischer Stahlrohre zum Nachweis von Dopplungen

ÖN EN ISO 3059, Zerstörungsfreie Prüfung – Eindringprüfung und Magnetpulverprüfung – Betrachtungsbedingungen

ÖN EN ISO 9934-1, Zerstörungsfreie Prüfung – Magnetpulverprüfung – Teil 1: Allgemeine Grundlagen

ÖN EN ISO 9934-2, Zerstörungsfreie Prüfung – Magnetpulverprüfung – Teil 2: Prüfmittel

ÖN EN ISO 9934-3, Zerstörungsfreie Prüfung – Magnetpulverprüfung – Teil 3: Geräte

ÖN EN ISO 17638, Zerstörungsfreie Prüfung von Schweißverbindungen – Magnetpulverprüfung

ÖN EN ISO 23279, Zerstörungsfreie Prüfung von Schweißverbindungen – Magnetpulverprüfung von Schweißverbindungen – Zulässigkeitsgrenzen

We work dedicatedly and with full commitment for our customers. We enjoy our work. You can see this in the way we treat each other and in the quality of our work.