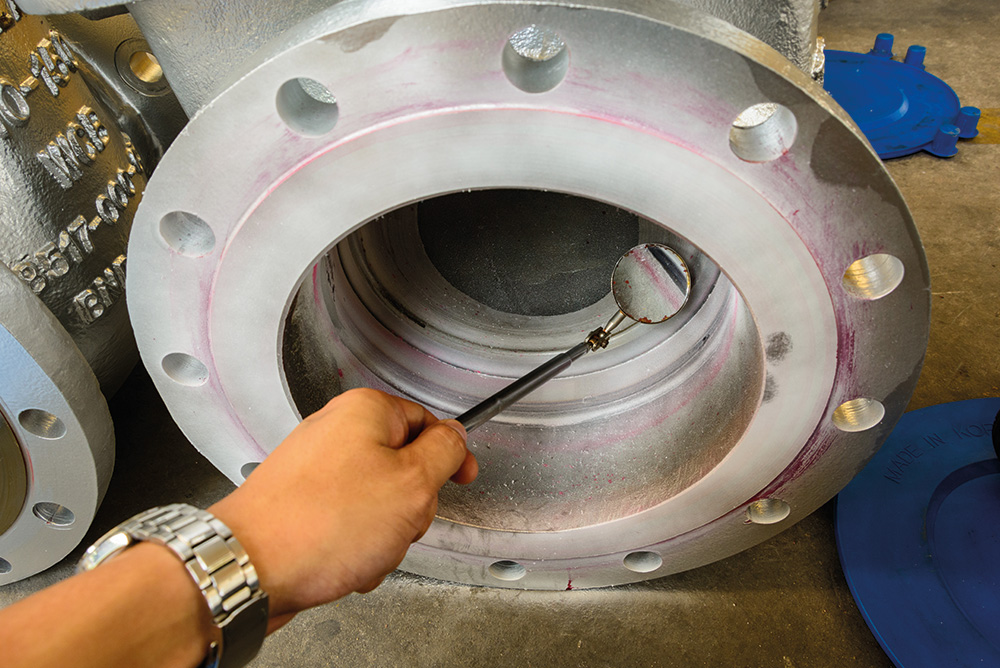

Is an optical inspection of a product or part for defects and blemishes as a conventional step in the production process at the end or after completion of the manufacturing of a product for quality control reasons.

Sight checks are also performed on operating parts. Visual inspection as a non-destructive testing method is standardised according to DIN standard DIN EN 13018 (General principles of visual inspection).

This standard is distinguishing between:

The distinction between direct and indirect visual inspections is defined in the standard as follows:

Are mechanical damage (scratches, cracks), dirt settlings, assembly errors, feathering, end-crater-cracks and undercuts.

Alongside colour changes (annealing colours at e.g. austenitic steels), surface roughness etc. can be discovered effectively.

We work dedicatedly and with full commitment for our customers. We enjoy our work. You can see this in the way we treat each other and in the quality of our work.