The penetrant test (according to ÖN EN ISO 3452-1: penetrant test, general principles) is a non-destructive testing method which uses capillary forces of fine surface cracks and porosities to make these visible. There is a distinction between dye penetrant test and fluorescent penetrant test.

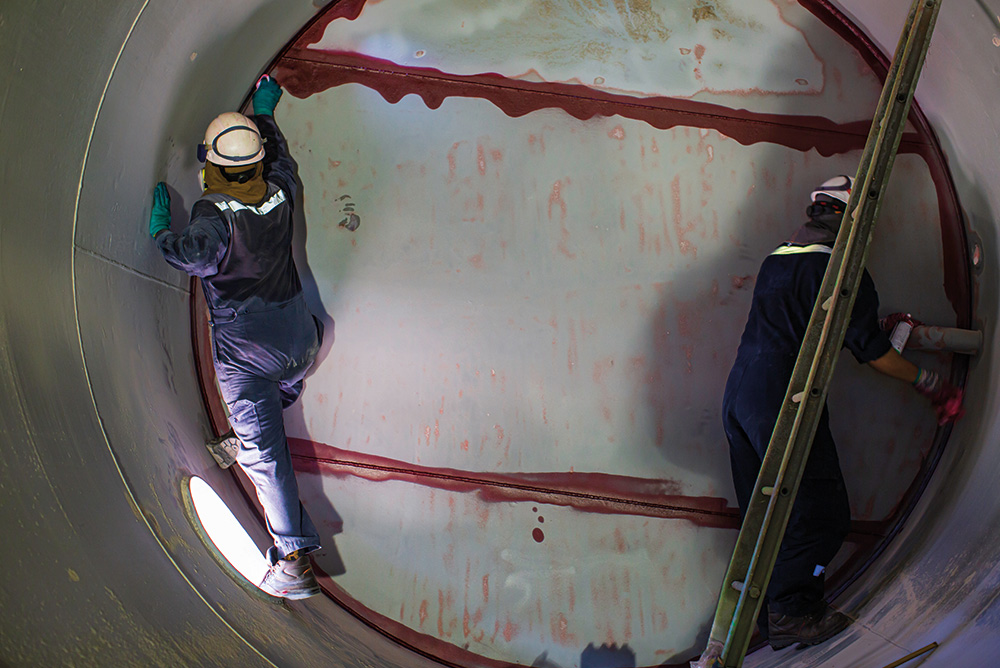

For this procedure the surface of the component to be tested is stripped of oil and fat remainders and afterwards the penetrant is applied. This can be achieved by using a brush, dipping in a bath or, in well ventilated areas, by spray coating (all of these mentioned methods are also called forced wetting).

The creeping ability of the penetrant is very high, uses capillarity of the finest material separations and possesses a high colour contrast for the developer.

After the exposure time, which depends on the material that will be tested, has elapsed, the surface is cleaned with water or a special cleaner, dried and then the developer is applied. The developer is a fine-grained powder (usually based on lime (chalk) suspended in water or solvent) that draws out the penetrant remaining in the fine cracks (pores) through the capillary action of its own cavities (absorbency).

Normally the penetrant (a dye solution) is red and the developer is white. The high color contrast makes it easy to locate the defects and determine the crack paths.

With the dye colour penetrant test it is possible to find cracks on the surface of materials easily (up to one thousands of a millimetre width). However, pseudo exposures can occur on rough or ridged surfaces. These indications are defects.

Furthermore this testing method does not indicate the depth of the defects concerning the intensity of indication: a delicate pink coloured defect does not necessarily indicate a less deep crack than a dark red indication.

When the ambient brightness is too low, fluorescent penetrants are used, which can be visualised with ultraviolet radiation. This testing method is considerably more sensitive than the dye penetrant test, since the fluorescent particles produce a luminance contrast. The human eye reacts far more sensitive to luminance contrasts compared to colour contrasts.

The penetrant test is applicable to all materials which allow a definite indication of surface defects (not poriferous), mainly used on metals, plastics (with limitations: e.g. Teflon), glazed ceramics and the like. For machine parts made of steel a solvent-based developer is applied due to the high corrosion susceptibility. For ferromagnetic (non-austenitic steels) the magnetic particle testing is performed.

DIN 25435-2, Wiederkehrende Prüfungen der Komponenten des Primärkreises von Leichtwasserreaktoren – Teil 2: Magnetpulver- und Eindringprüfung

ÖN EN 571-1, Zerstörungsfreie Prüfung – Eindringprüfung – Teil 1: Allgemeine Grundlagen

ÖN EN 1371-1, Gießereiwesen – Eindringprüfung – Teil 1: Sand-, Schwerkraftkokillen- und Niederdruckkokillengußstücke

ÖN EN 1371-2, Gießereiwesen – Eindringprüfung – Teil 2: Feingußstücke

ÖN EN 2002-16, Luft- und Raumfahrt – Metallische Werkstoffe; Prüfverfahren – Teil 16: Zertörungsfreie Prüfung, Eindringprüfung

ÖN EN 10228-2, Zerstörungsfreie Prüfung von Schmiedestücken aus Stahl – Teil 2: Eindringprüfung

DIN EN 10246-11, Zerstörungsfreie Prüfung von Stahlrohren – Teil 11: Eindringprüfung nahtloser und geschweißter Stahlrohre zum Nachweis von Oberflächenfehlern

ÖN EN ISO 3059, Zerstörungsfreie Prüfung – Eindringprüfung und Magnetpulverprüfung – Betrachtungsbedingungen

ÖN EN ISO 3452-2, Zerstörungsfreie Prüfung – Eindringprüfung – Teil 2: Prüfung von Eindringprüfmitteln

ÖN EN ISO 3452-3, Zerstörungsfreie Prüfung – Eindringprüfung – Teil 3: Kontrollkörper

ÖN EN ISO 3452-4, Zerstörungsfreie Prüfung – Eindringprüfung – Teil 4: Geräte

ÖN EN ISO 3452-5, Zerstörungsfreie Prüfung – Eindringprüfung – Teil 5: Eindringprüfung bei Temperaturen über 50 °C

ÖN EN ISO 3452-6, Zerstörungsfreie Prüfung – Eindringprüfung – Teil 6: Eindringprüfung bei Temperaturen unter 10 °C

ÖN EN ISO 12706, Zerstörungsfreie Prüfung – Eindringprüfung – Begriffe

ÖN EN ISO 23277, Zerstörungsfreie Prüfung von Schweißverbindungen – Eindringprüfung von Schweißverbindungen – Zulässigkeitsgrenzen

ASTM E 165, Standard Practice for Liquid Penetrant Examination for General Industry

ASTM E 1417, Standard Practice for Liquid Penetrant Testing

We work dedicatedly and with full commitment for our customers. We enjoy our work. You can see this in the way we treat each other and in the quality of our work.